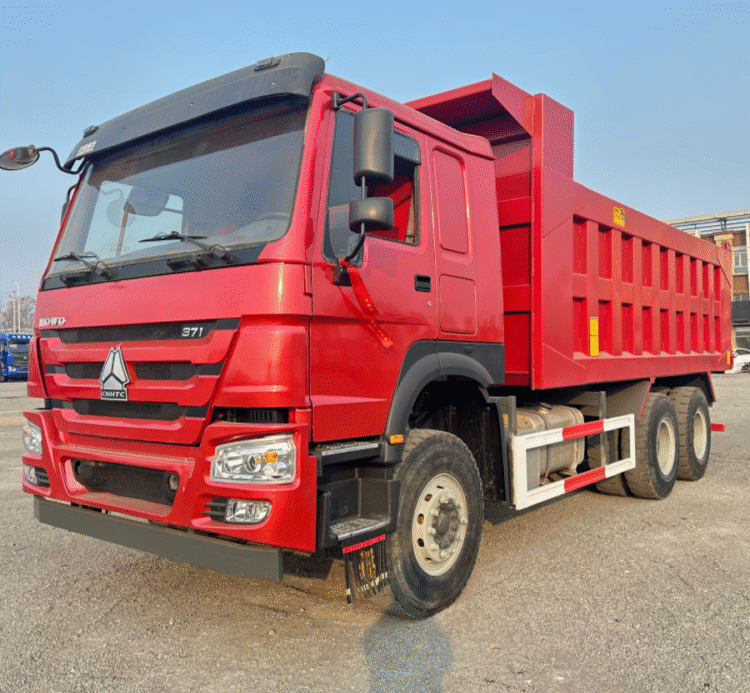

In the busy and challenging business of heavy construction projects, round-the-clock material transport, long working hours and stringent working conditions are the rule of the day, and the equipment utilized often determines the success or failure of a project. The HOWO 371 dump truck stands out in this aspect with its perfect combination of reliability, flexibility and affordability, which is exactly the ideal equipment that construction industry professionals have long looked for.

Dust-proof Design for Harsh Construction Site Environments

Three-stage Air Filtration System

Building construction, especially in arid climates or large highway building projects, is often filled with fine dust, which tends to permeate mechanical equipment and cause premature wear. The HOWO 371 dump truck meets the challenge with its highly effective three-stage air filtering system. The pre-filter intercepts large particles of debris first, then the oil bath filter captures smaller pieces, and finally the air filter provides clean air that enters the engine. Such intricate filtering minimizes engine damage and allows the truck to run smoothly even in dusty weather. For example, on highway construction projects in desert areas, where other trucks stop work more frequently because of engine failure resulting from dust, the HOWO 371 dump truck could run with minimal interruptions to help make it possible to keep the project proceeds as planned.

Dual Protection of Engine and Brake System

Safety first in construction, and long-distance transportation and high slopes are likely to be hazardous to the brake system of the vehicle. The HOWO 371 dump truck is equipped with a 200L water tank for cooling as standard equipment, which can provide sufficient coolant to maintain the engine at the most efficient operating temperature during conditions of long-term heavy-load operation. In addition, its water spray device can be referred to as the “guardian” of the brake system. Trucks on mountain road construction projects often need to brake frequently on long downhill sections. When this happens, the water spray system will start to cool the brake system to prevent overheating and possible brake failure. The dual protection arrangement not only protects the vehicle but also the operator, reducing the likelihood of accidents as well as the staggering cost of downtime due to breakdowns.

Climate and Regulatory Compatibility

Cold Weather Start Solution

Construction operations are conducted in every kind of climate, from the scorching sun of the desert to the freezing cold of the polar nations. In cold climates, the HOWO 371 engine’s electric air intake heater is a valuable feature. It allows the truck to start up under any conditions even at a temperature as low as -30°C, which is low enough to make most other machines “break down”. By preheating the intake air, the engine’s combustion process is optimized for reliable ignition and operation. In an Arctic construction of an infrastructure development project, due to the short construction season and tight schedule, the cold start ability of the HOWO 371 dump truck ensured that construction would not be delayed, allowing the contractor to complete the job on schedule and avoid additional costs.

Modular Chassis that Meets Emission Standards

With the world emphasizing environmental sustainability, construction machinery must meet strict emission standards. The chassis modularity of the HOWO 371 dump truck provides unparalleled flexibility in this regard. Whether it is Europe, which has the high Euro VI emissions, or in other regions where emission standards are constantly changing, the pipe layout of the exhaust as well as the after-treatment system can be simply adjusted because of the modularity in its body. This adaptability does not only protect construction companies from huge fines because of non-adherence, but also allows companies to build the perception of being environmentally friendly, enhance their company image, and thus have greater opportunities for projects.

Cost-saving Operating Mechanism

Simple and Reliable Engine Structure

For construction companies, control of operating costs is a must. The big pump engine of the HOWO 371 dump truck meets this with its simple and reliable structure. Compared with modern engines based on sophisticated electronic control systems, the big pump engine has a simple design and convenient maintenance and repair. Its parts are highly adaptable and convenient to obtain, greatly reducing the time and cost of procuring replacement components. When the truck breaks down, individuals performing maintenance can readily locate and repair the issue without using specialized diagnostic equipment or extensive technical knowledge. On large construction projects, every minute of downtime will be financially costly. The low-maintenance engine of the HOWO 371 dump truck ensures that the vehicle can be quickly restored to operation, which acts as a good backup to the overall profitability of the project.

Quick Repair Reduces Downtime

The easy-to-repair feature of the HOWO 371 dump truck is a big advantage to construction activities. Its simple engine design and easy-to-reach parts enable simple repair and maintenance activities to be carried out efficiently even in extensive construction sites that lack complex maintenance shops. For example, in a remote construction project far from the city center, if there is a slight engine failure, local maintenance personnel can readily procure the required parts and complete the repair to reduce the impact on the project schedule. This ability to reduce downtime not only saves the cost of equipment idle time, but also maintains continuity of the entire construction process.

Conclusion

The HOWO 371 dump truck is not just a means of transport, but a comprehensive solution for heavy construction projects. It can operate stably in harsh conditions, adapt to various climates and regulatory requirements, and achieve economical and efficient operation, making it a valuable asset for any construction site.

Rhino Truck operates used HOWO 371 dump trucks. We have rich export experience and look forward to cooperating with you.